Sustainability in Ophthalmology: A Wake-Up Call for all stake holders

Published: 22/07/2024, Reading time: 5 minutes

Sustainable practices for Ophthalmologists

Modern ophthalmology faces a critical challenge: the need to implement sustainable practices and minimize the ecological footprint of our field. Given the high environmental impact associated with ophthalmic practices, it is time for eye surgeons around the world to take action.

The Urgency of Sustainability in Eye Surgery and Hospitals

The World Health Organization has identified climate change as the greatest health threat of our time. Globally, the healthcare sector contributes to approximately 5% of all greenhouse gas emissions, with this figure rising to 10% in the United States. A significant part of this impact comes from the high waste production and emissions related to single-use ophthalmic devices and equipment used in surgeries. For instance, a single cataract surgery in the UK can generate up to 130 kg CO₂ equivalents, which is comparable to driving a car for 310 miles (American Academy of Ophthalmology) (SpringerLink).

Waste in Ophthalmology

Ophthalmology generates a staggering amount of waste daily. A typical cataract surgery in the US uses single-use eyedrops, phaco tips, tubing, gowns, and other accessories, resulting in vast amounts of packaging and clinical waste. This is driven by a prevalent "single-use mindset" in many developed countries (American Academy of Ophthalmology) (ESCRS).

Successful Models and Potential Approaches

Successful models like the Aravind Eye Care System in India demonstrate that sustainability and patient safety can coexist. By using reusable materials and efficient sterilization processes, Aravind has reduced the CO₂ output per cataract surgery to about 6 kg, without compromising safety standards (SpringerLink).

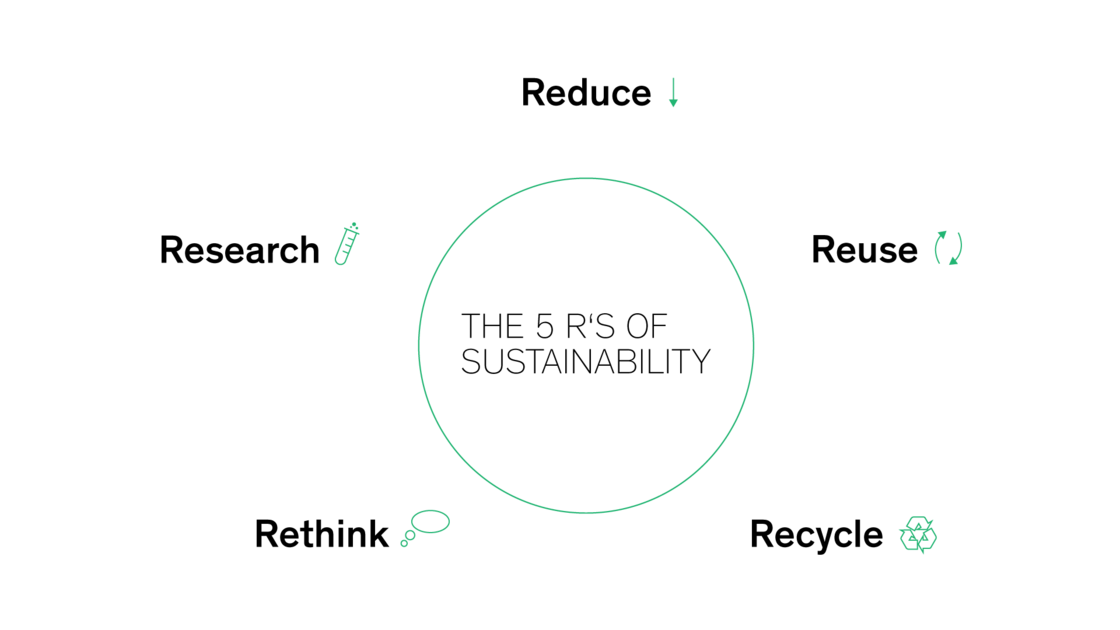

The 5 R's of Sustainability

To reduce environmental impact, ophthalmologists should adhere to the principles of the 5 R's: Reduce, Reuse, Recycle, Rethink, and Research. Practical measures include:

- Reduce: Lower energy consumption by using LED lights and motion sensors.

- Reuse: Optimize sterilization processes and use reusable materials.

- Recycle: Properly dispose of waste and prefer recyclable materials.

- Rethink: Question current practices and seek sustainable alternatives.

- Research: Develop new methods and technologies to further minimize environmental impact (SpringerLink) (ESCRS:Home).

Oertli's Sustainability Initiatives in Ophthalmology

Oertli commits with several initiatives such as innovative water treatment systems, solar energy investments, eco-friendly packaging, and local sourcing to reduce waste and carbon emissions.

Cleanroom

- Water Treatment Plant: Oertli has its own water treatment facility for cleaning parts used in the cleanroom.

- Water Recycling: The water cycle is recycled, meaning the water is not entirely replaced daily.

Sustainable Energy

- Solar Panels: Investing in a comprehensive installation of solar panels on the roof surfaces of the new Lean Factory. The solar panels cover 10% of the baseload with solar energy (1000 sqm/200,000 kWh of photovoltaic panels).

- Waste Heat Utilization: Heating is provided sustainably using waste heat from CNC machines.

- Cooling Systems: Cooling in the new building will use water panels, which cool emission-free by extracting heat instead of traditional air conditioning.

- E-Mobility: Promoting e-mobility with charging stations for electric vehicles.

Packaging and Consumable Materials

- Disposable Product Packaging: Packed in blisters or sterile pouches made of PETG with a Tyvek seal (including recycled material) and PET-O/PP film with sterilization paper. Environmentally friendly disposal as no toxic gases are produced during incineration.

- Cardboard Boxes: Products are packed in recyclable cardboard boxes, which consist of a proportion of recycled material.

- Reusable Products: Offering some consumables in reusable variants, such as I/A cassettes for CataRhex 3 and Faros, which can be sterilized ten times.

Local Production and Sourcing

- Local Production: 75% of Oertli's added value originates locally at the production site in Berneck, minimizing the need for material transport.

- Local Suppliers: Over 80% of suppliers are located in Eastern Switzerland, Vorarlberg, or Southern Germany, ensuring short transport distances and reducing CO2 emissions.

Recycling and Waste Management

- Titanium Recycling: Residual titanium from the production of parts like phaco tips and trocars is recycled.

- Material Use: Using pure materials instead of composites to facilitate recycling.

- Standard Waste Separation: Separating electrical waste, batteries, glass, PET, and metal for proper disposal.

- Oil-Cooling Systems: CAD/CAM machines have been converted from water cooling to oil cooling in a closed loop.

Lean Factory

-

The primary objective of the Lean Factory is to increase the efficiency of work processes and production volumes to achieve set growth targets. With an investment of around 30 million Swiss francs, this new building underlines the commitment to a sustainable future and the clear commitment to Switzerland as the only production location.

These initiatives highlight Oertli’s commitment to sustainability across various aspects of its operations, from energy use and waste management to local sourcing and digitalization, ensuring a greener future for ophthalmic devices like phaco systems, vitrectomy machines, and surgical instruments, while supporting ophthalmologists worldwide.

A Call to Action for everyone in Ophthalmology and beyond

It is evident that ophthalmology significantly contributes to environmental degradation. As stake holders in eye surgery, we have a duty to protect not only our patients but also our planet. It is time to reassess our practices and make sustainability a core component of ophthalmic care. The future of our patients and our earth depends on it.

Phaco History

Check out our blog about the history in phacoemulsification - and more.

Robotics and AI in ophthalmology

Discover the latest innovations and get all the information you need on this topic.

Glaucoma and HFDS

HFDS shows its love for the eyes by offering a minimally invasive and gentle approach to glaucoma treatment. Check it out.

Oertli data on file

This blog post now accurately references the provided sources in the correct order, ensuring clarity and proper attribution of information. If you have further adjustments or additions, feel free to ask!

This blog was written with the support of artificial intelligence (Chat-GPT).